Welcome to the fourth article in the Design for Manufacturing series! In this article, new BDR Editor Andrew Cousins shares a few insights into how you can integrate joining processes, specifically welding, into your next design project.

All in Short Course

Design for Manufacturing Series: Additive Manufacturing

This article examines the transformative impact of 3D printing across various industries, from aerospace to construction and even culinary arts. It offers practical design tips for optimizing your prints, such as adjusting support structures, infill percentages, and finishing techniques to enhance both functionality and aesthetics. Learn how to leverage these insights to elevate your projects and harness the full potential of this versatile technology.

Design for Manufacturing Series: Subtractive Machining

In an article published a few weeks ago, I gave a brief overview of a variety of manufacturing processes. Now, I will further discuss the first set of processes – subtractive machining.

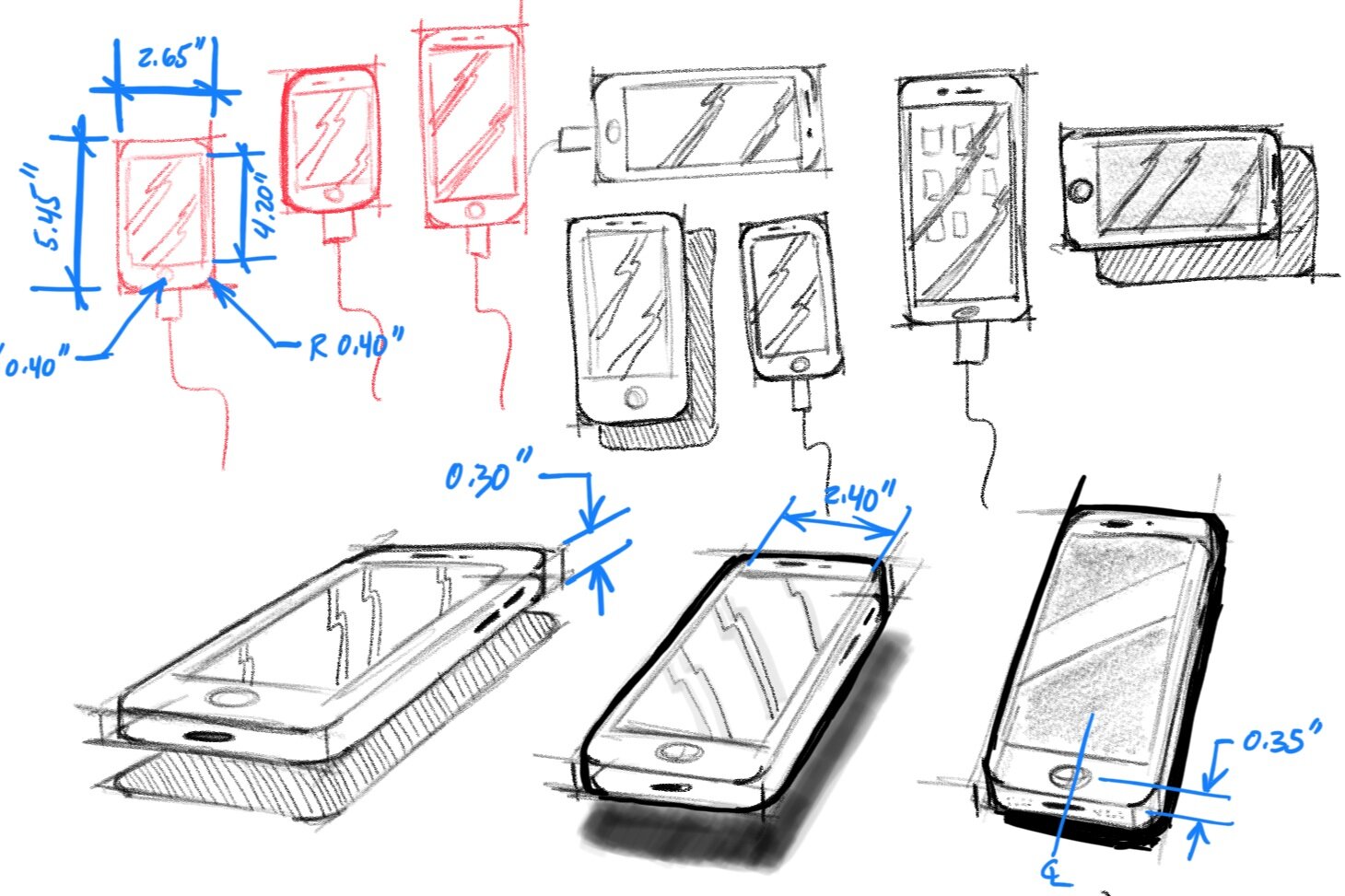

Bring Your Sketches to Life with Simple Shading and Shadow

Relatively simple things can be done to liven up your sketches. This article presents a number of common techniques to try.

A Brief Overview of Manufacturing Processes

As designers, we should be aware of as many manufacturing processes as possible. The more processes we know about, the more effectively we are able to manufacture a good product. This article will provide you with a short list of processes in which you can find inspiration for how to best make your product.

Design Thinking Part 5: Tips and Anecdotes

In this final part of the Design Thinking series, I highlight empathy development as a distinguishing factor in the Design Thinking approach and describe 6 reasons why some people fail to find success with Design Thinking.

Design Thinking Part 4: Framing and Reframing Design Problems

Problem framing is about uncovering the actual problem worth solving – which is often hidden to everyone when the design process begins. A key part of framing and reframing is to see the problem from various perspectives and to search for best match between the problem frames and the solution candidates. This article provides the basics of problem framing and positions it as the backbone of Design Thinking.

Visual Thinking Exercises for Engineers

Visual thinking skills enables good sketching. Good sketching facilitates rapid design iteration. Good design emerges from significant iteration. Based on this logic, visual thinking skills are foundational to good design.

Learn to Sketch: Shading and Shadowing Cylinders

Until recently, how to shade and shadow cylindrical objects has been a mystery to me. I had known there should be areas on the surface shaded lighter and others darker, but I didn’t quite know where those should be. Understanding the physics and practicing the sketches in a detailed way (a few times) helped me lock in the core concepts. Now I can sketch them quickly without trouble. This article shares the physics and provides a step-by-step process for skill building.

Design Thinking Part 3: Design Thinking as a Mindset

This part of the Design Thinking series describes the mindset of expert designers. The article argues that the mindset of Design Thinking is enabling and freeing because it represents the beliefs that the designer uses to choose good design actions at appropriate times given the unique characteristics of the problem being solved.

Design Thinking Part 2: Design Thinking as a Step-by-Step Process

Design Thinking is not new. It’s been around for decades. The first attempt to turn it into a process was in 1969. Contemporary forms of that process still exist today, the most popular being the 5-step process introduced by the Stanford Design School in 2005. This article describes that process and other techniques that will help you try-out Design Thinking.

Design Thinking Part 1: Basic Concepts and Principles

Design Thinking is a powerful and popular topic, but it is also illusive and ill-defined. This article demystifies Design Thinking just enough so you can begin benefitting from what it offers. This is the first of a 5 part series on Design Thinking, where this first part provides basic definitions, view points, history, and Design Thinking exercises.

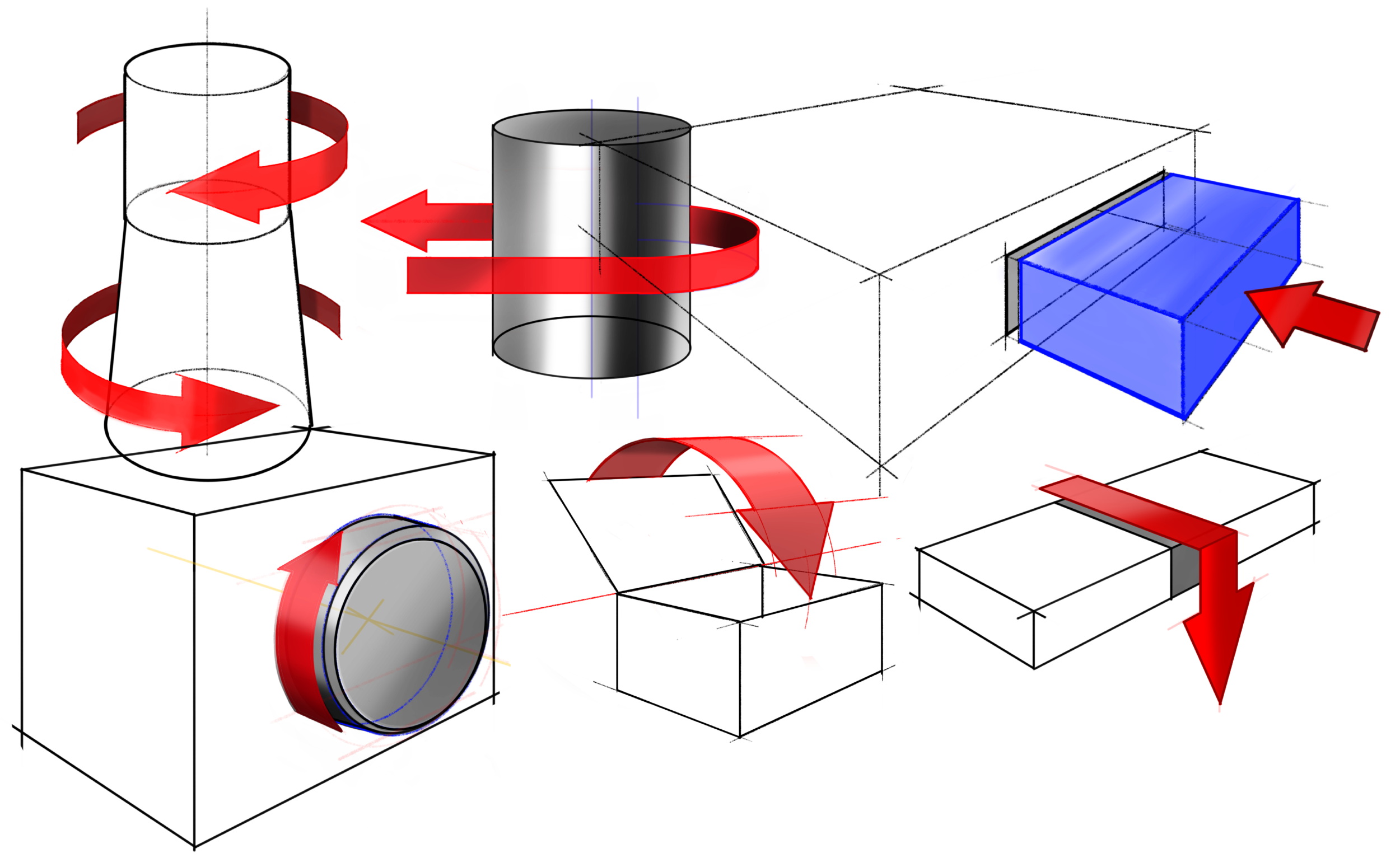

Learn to Sketch: Part 4

Enhance your sketches with motion arrows, annotations, and dimensions.

Learn to Sketch: Part 3

As engineers we often need to conceptualize (and sketch) specific geometry such as specific wing shapes, specific gear trains, or a new component that needs to fit in a specific spot on an existing device. In this article, I’ll share a few insights and exercises designed to help you produce sketches of specific geometry, including cross-section sketches, and exploded-view sketches.

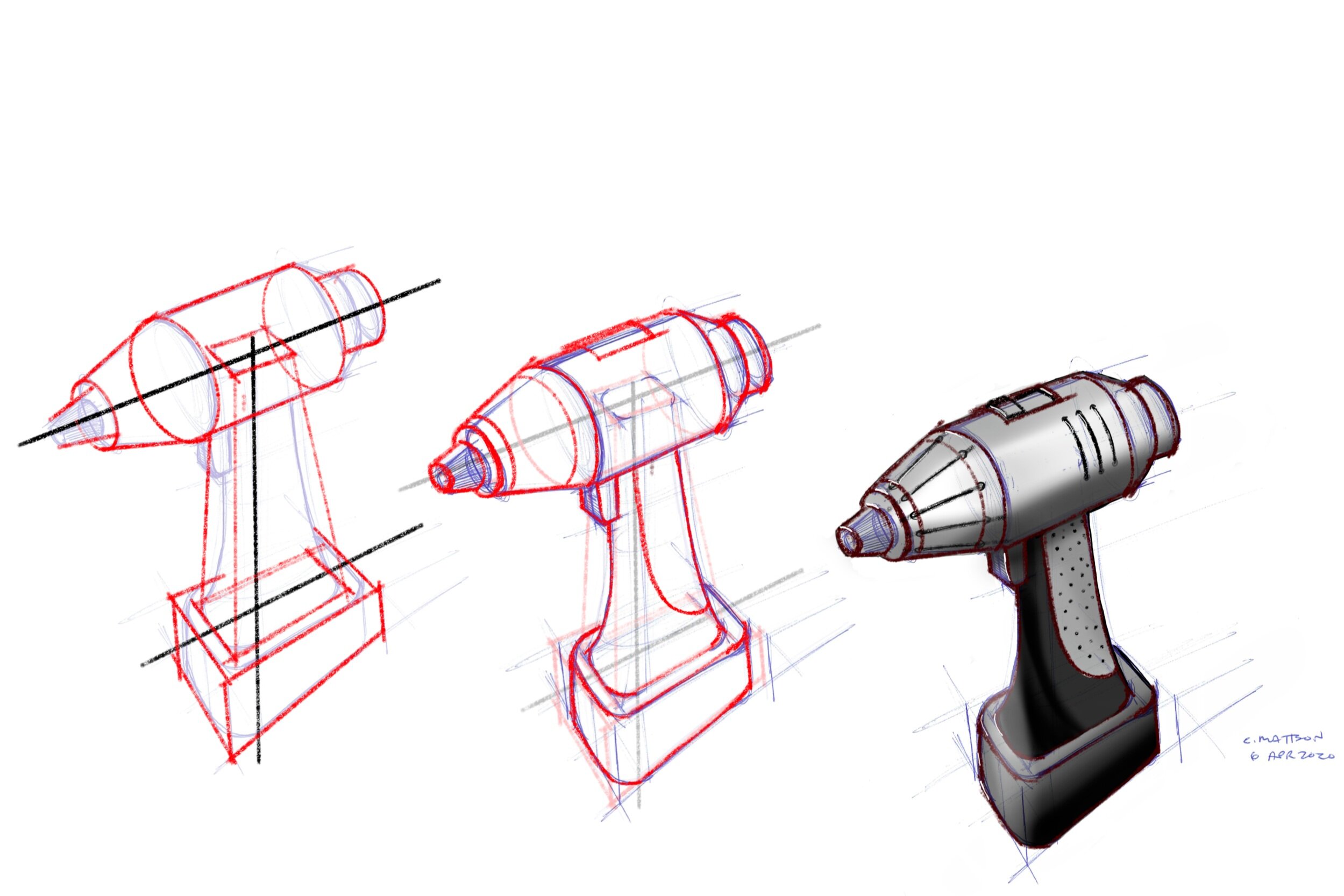

Learn to Sketch: Part 2

Three new sketching exercises, plus a three-step sketching approach and mathematical rules that when followed produce realistic sketches.

Learn to Sketch: Part 1

Learn the basics of product sketching. Even with 10 minutes a day, you will be surprised by the progress you can make. Try it out with part 1 of this learn to sketch series.