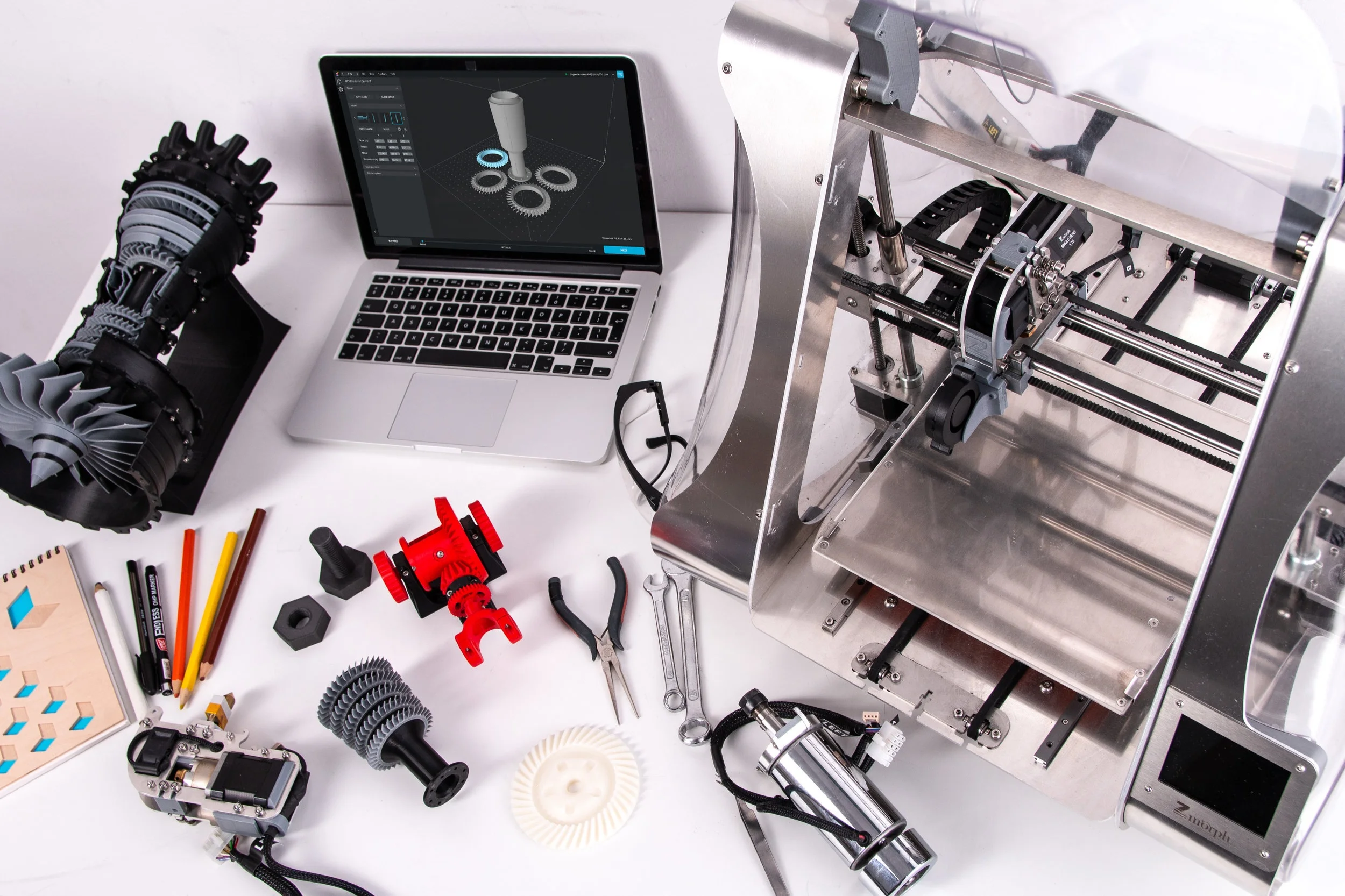

So You Think You Want to 3D Print Your Next Design?

“Most engineers have experienced the thrill of going from a CAD model to a 3D Printed part they can hold in their hands. It is rewarding to see your ideas in physical form so quickly and effortlessly. Many then ask themselves, why can’t I use 3D printing for production?”

The good news is that, you probably can. With many different processes for 3D Printing (also called Additive Manufacturing or AM), you can make a wide range of complex geometries in an increasing variety of materials without the cost of tooling or the extensive labor required for many other manufacturing techniques. While the resulting material properties, surface finish, and dimensional accuracy is often somewhat different than traditional processes like injection molding, the gaps are narrowing rapidly and the properties are more than adequate for many products. Production speeds continue to increase and costs decrease. Unless you are very actively engaged in AM research, you will likely find that you can 3D print with more materials and with better results than you realized. Plus, AM lets you make complicated geometries that are impractical or infeasible with many other processes.

The bad news is that you probably shouldn’t. It probably doesn’t make sense to use AM manufacturing techniques for production unless you are leveraging its strengths. Ironically, the reason for this goes back to its attractive benefit: the cost of the first part is not much different from the 100th or 1000th part. Thus, while you may be able to get this new part in a few hours or a day, your production rates may be measured in parts per day rather than parts per hour (or seconds). Meanwhile, the first part from a casting or molding might take days or weeks longer but then the incremental costs go down and production rates increase dramatically.

Why then is there so much hype about AM? AM does open new exciting opportunities. However, you must decide if that door leads you in the right direction. For example, if the ability to make complex geometry reduces operational costs sufficiently, then AM increases product value. If you want to customize each product for a customer, then the reduced tooling costs of AM are a game changer. Unfortunately, too often engineers use AM to make the same products that they could make with a traditional process. While this is appropriate for building early prototypes, it does not lead to a product for which AM is an economical production alternative.

If you want to move from using AM for prototyping to production, you must identify specific benefits that you want to obtain. You might start by asking, “How could the part design be changed without the constraints of traditional manufacturing methods or the costs of part-specific tooling?”

However, the most exciting opportunities are not found in reimagining a single part. The benefits increase when the design scope is expanded with a new eye towards what is possible. Can you look at an assembly and see the possibility of a single part? Could a warehouse full of spare parts be replaced by a few 3D printers and an inventory of solid models? Rather than have fixed models, could I customize every item?

For example, innovators looked at individual creativity and imagined a world where people could sell their ideas without having to manage the manufacturing themselves (Shapeways). Others looked at brackets and wires on teeth and imagine a new way of doing orthodontics (Invisalign). The more you adjust your product, your distribution, supply chain, and even marketing to the capabilities of additive manufacturing, the more likely you are to observe a strong economic benefit. Often, it takes more than just AM to make a revolutionary new approach work. Invisalign didn’t just need to 3D print aligners. They needed new kinds of CAD software that would allow for automated design of each retainer in the series. They needed to find a way to process thousands of visually identical retainers and yet get each one to the right customer in the right order. When we expand the scope of our thinking with AM, we open the door to amazing discoveries.

If you are ready to accept the challenge of designing for AM, here are a few thoughts to keep in mind:

AM is actually a term for many different processes that each have their own strengths and capabilities. Take the time to understand them so you can work them rather than fight against them.

Like all processes, AM produces unique artifacts and features. Rather than try to match surface finish, accuracy, or material properties of another manufacturing method, design the product for the AM process.

While AM opens new freedom, it also brings new challenges. One area that is particularly challenging is adapting quality assurance processes designed for mass production for customized parts and/or complex geometries.

Just like a comfortable pair of shoes matches the shape and mechanics of your feet, your design should be well matched to the chosen manufacturing process. If there is a problem, it is typically the design that must be modified to improve the fit.

To cite this article:

Crane, Nathan. “So You Think You Want to 3D Print Your Next Design?” The BYU Design Review, 16 Oct. 2019, https://www.designreview.byu.edu/collections/so-you-think-you-want-to-3d-print-your-next-design.