Is Documentation Valuable to the Design Process?

Engineering students don’t like writing reports. This was especially obvious to me during my capstone design project my senior year of undergrad. Anytime a report was required or due, there was a barrage of whining and complaining from the students - and sometimes the mentors and instructors complained too! I have also been a teaching assistant for several design classes, and I’ve been approached by students telling me why they felt like their reports were useless.

These complaints never sat well with me. During my engineering internships, documentation work was a significant part of what I did. I wrote assembly instructions, maintenance manuals, edited drawings, and did engineering specs for our quality assurance program. The work was tedious - but also technical, challenging, and rewarding. Since documentation was such a big part of my internship, it often bothered me that so many people complained about it. I wanted to learn how other professionals and firms “in the real world” practiced documentation. And last spring, I finally had my chance to find out.

Recently, I took a class called Global Product Development. For this class, we visited 21 different product development companies, ranging from industrial design firms, engineering analysis firms, to manufacturing centers. At each company, I asked someone a variant of this question: Do you think documentation is valuable to the design process? If you do, why?

The author taking notes in the background during a visit to a company who designs and manufactures microscopes.

Want to know what they said? Here are some samples:

“You need to embrace documentation. Even in a start-up, you’ll waste a lot of effort if you don’t document well.”

“About 2/3 of my time is on documentation.”

“It’s an evil that you need… I totally hate it, but it’s needed.”

“I hate reports but they’re important.”

“Without writing, our start-up would not be here.”

“It’s boring but important.”

“[Our customers] come to us because everything needs to be documented and validated… For engineers, documentation is everything.”

Seeing any similar trends? The first thing I noticed is that product design professionals - whether they are industrial designers, engineers, or manufacturers - all found value in documentation. Most of them did not like it, but they all felt like it contributed value.

I also observed that every company has a different documentation practice. The documents they prepared or wrote depended on what kind of product they were working on, and how they were contributing to the product development process. Some documents were as simple as scanning in your hand sketches to a database, while other documents communicated the results of rigorous engineering analysis.

Since this experience, I’ve come to believe the following about documentation in design:

The designer should minimize administrative costs when it comes to documentation

Documentation preserves design decisions made by the design team in a way that 1) saves the design team work in the future, or 2) is communicable to stakeholders and customers outside of the design team. Many of the professionals I talked to said that well-prepared documentation saved them future effort. However, preparing documentation comes with an administrative cost that does not immediately contribute to the design process. An industrial designer told me that he minimizes administrative costs in anything he prepares, so he doesn’t lose time for other design activities. Likewise, remember that you are free to challenge the documents you are writing to minimize your own administrative work.

Documentation becomes more valuable for complex products or activities

One of the companies we visited designed artisan glassware. I was looking at their engineering drawings, and noticed that they did not have any dimensions or tolerancing. I asked the manager why the drawings did not have dimensions, to which he said the dimensions did not matter. The main constraint was that the glassware was beautiful. As long as the glassware looked beautiful, and matched the image on the drawing, it was good enough to be sold.

However, the day before, we had visited a microscope manufacturing company. Unlike the glassware company, their drawings all had dimensions. Why? Well, a microscope is much more technical than a drinking glass! Microscopes are precise instruments with many challenging constraints, and deviations in dimensions would subvert the product’s performance. The complexity of a document is reflective of the product it is for. If you’re working on a complex or technical product, you can expect the preparation of a document to be more tedious or difficult.

Documentation becomes more valuable as the product progresses through its stages of development

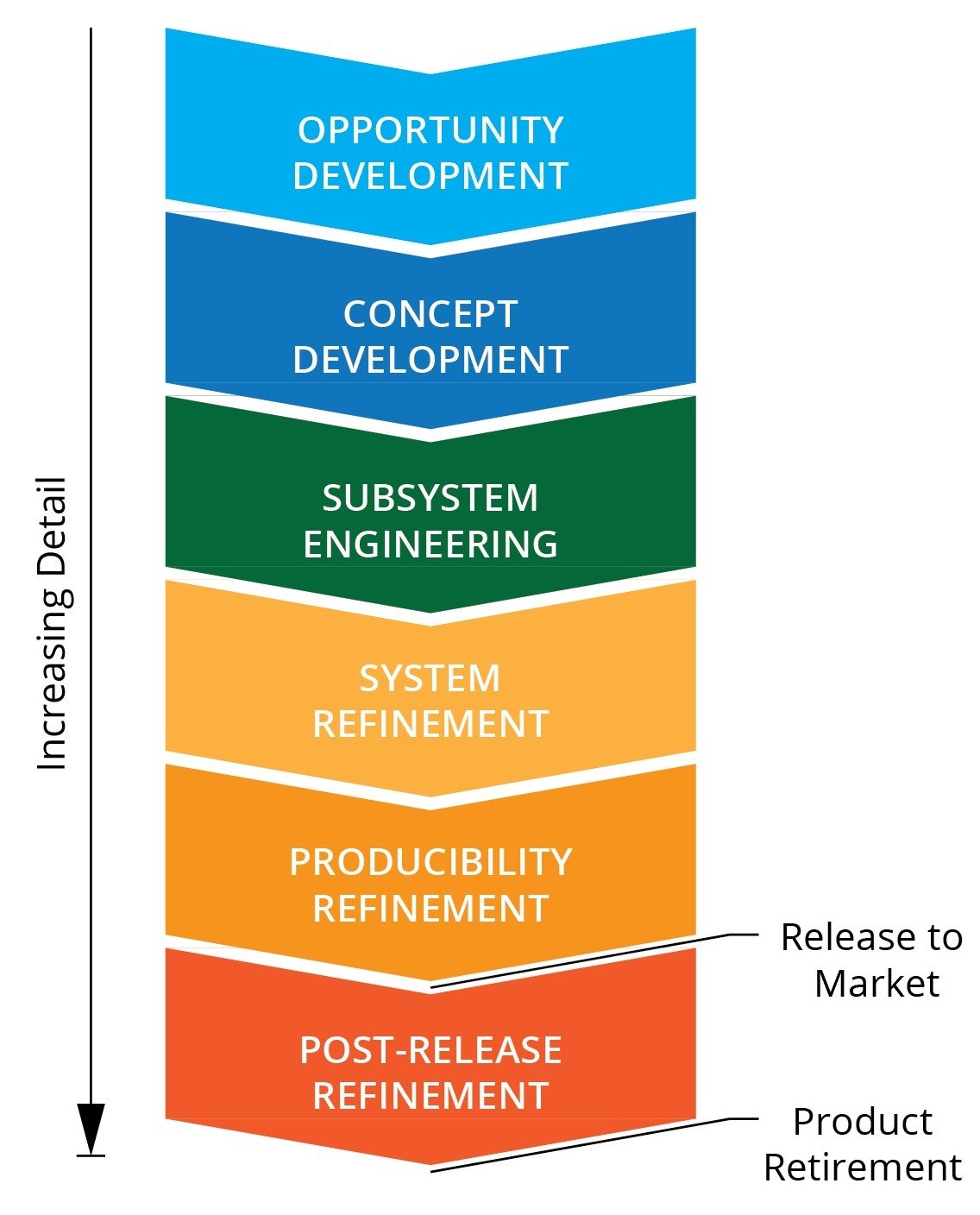

Stages of development describe the state of a product as it grows from an initial idea to a producible good. As the product evolves from an identified need to something on the market, more and more decisions are made to define the design until it is ready for consumer purchase and use. The figure below describes what these stages are.

From Engineering Design Essentials, 2023, by Chris Mattson.

The kind and amount of documentation the design team uses will change over the course of a product’s development. For example, I asked an industrial designer if they prepare design reports. He said, “No, why would I do that,” and shrugged me off. While they may not prepare formal reports like an engineering firm would, they do communicate their ideas in the form of sketches, renders, and PowerPoints. Being primarily engaged in opportunity development and concept development, a sketch on a sticky note may be all that is required to communicate what the design is. But we also visited an engineering firm whose primary output is engineering reports. The preparatory analysis for these reports takes a long time to prepare, but their customers are engaged in subsystem engineering and system refinement. During these stages of development, engineering analysis is used to make and justify every critical design decision. The engineers must prove that the decisions are made well - hence the reports. As we progress through the stages of product development, we will need to verify, validate, and communicate an increasing number of technical decisions with other product development stakeholders. The documentation to record these decisions becomes harder to prepare, but more useful to the successful execution of the design process.

Conclusion

I believe that designers who can prepare thoughtful documents better manage the complex realities of design and reduce the number of self-inflicted problems. In the future, if a student is complaining about the administrative effort being poured into a document, I would ask:

1) Can you prove that your design decisions have been sufficiently captured without the creation of this document, or that this document won’t help you capture your design decisions?

2) What is the critical decision being documented here, why does it need to be remembered, and to whom does it need to be communicated? How should this document be prepared so that the decision is captured?

Regardless of what their specific philosophy or practice around documentation was, every firm we visited agreed that documentation is valuable to the design process. Preparing and writing good documentation will be a crucial part of your own design practice. So next time the design report comes your way, feel free to complain a little – but don’t be afraid to dive in.

To cite this article:

McKinnon, Samuel. “Is Documentation Valuable to the Design Process?” The BYU Design Review, 11 Jul. 2024, https://www.designreview.byu.edu/collections/is-documentation-valuable-to-the-design-process.