Good Design from the Summer of 2024

In the next few weeks, millions of students across the world will be returning to school after a hot, humid, and, hopefully, enjoyable summer. The summer of 2024 brought some interesting things politically, socially, environmentally, and of course technically. We asked four members of the BYU Design Review editorial board to share thoughts about a design, technology, or innovation that they discovered or learned about during the summer. Here’s what they found.

Bathroom in Rome Italy

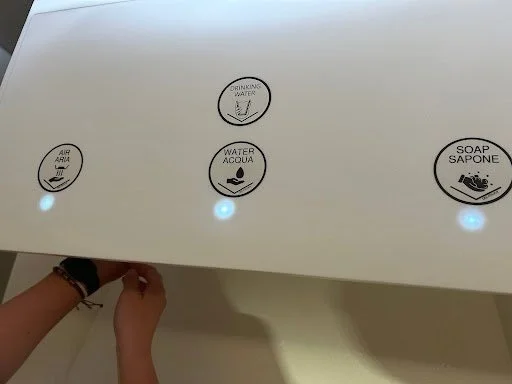

Over the summer, I had the chance to take part in a study abroad program that took me to Spain and Italy. During our layover at the Leonardo da Vinci–Fiumicino Airport, I was astonished by how beautifully designed the airport was. Oddly enough, the most amazing part was the design of the sinks in the bathroom. The bathroom is probably one of the dirtiest and most cramped places in an airport, but the people who designed this airport really kept these problems in mind. Instead of needing to move around the bathroom to locate the sink, soap, and hand dryers, they combined all three into a single station, complete with backlit mirrors hanging above each ledge. Each station had three sections triggered by touchless sensors including labels above each of the sensor lights. On the right was the soap, the middle housed the water, and on the left, the hand dryer.

This truly was an amazing design manufactured to keep the user in mind. I really appreciated the attention to detail by placing the soap on the right-hand side, a place where most bathrooms keep their soap. Another detail was in the labeling; both the English and Italian words were used, along with easy-to-recognize symbols. Overall, I give this design a 10 out of 10 because of the ease, convenience, and innovation. The fact that I’m still obsessing over this bathroom even three months later speaks volumes to just how good of a design it is. - Emelia Sunday

Self-healing Concrete

I was rather surprised when I first learned this summer that concrete is the world’s second most-consumed resource, only behind water [1]. Concrete is critical to modern infrastructure, but it is expensive to produce and must be replaced when it is damaged. In the US, concrete upkeep requires $12 billion in expenditures every year, and much of this is road repair [1]. A common sight for road commuters is seeing road repairs due to deteriorating concrete. Thus, engineers and researchers have formed a new self-healing concrete. This concrete uses water-activated bacteria to seal cracks in concrete, which lengthens its lifespan more than 15 years and decreases upkeep costs [2]. Although still in development stages, this technology could revolutionize the commercial concrete industry.

This graphic illustrates the process of healing cracks in concrete. Bacteria mixed into the concrete as an aggregate imparts this self-healing ability [2]. This is also shown in the image below of concrete that has repaired itself. The top section of concrete does not have bacteria, whereas the bottom layer does.

Self-healing Concrete Results over time [3]

This technology employs a classic design principle: improving upon good design. Concrete has been used extensively since Roman times and has, over time, been gradually improved upon as production methods became industrialized and the best materials were pinpointed to increase strength and lifespan. Self-healing concrete represents the next iteration in continuing to improve the time-proven design of concrete for building structures. Often, good designs are made by synthesizing tried-and-true techniques with cutting-edge technology. - Dylan Conover

Water Park Attraction

I attended a family reunion in Idaho last summer. As part of the activities, we visited Silverwood Theme Park, which has a water park connected to the main area (with all the rollercoasters and other typical rides). A few months ago, the park opened up a new water attraction called Eagle Hunt this year. The slide’s design is a unique take on traditional water slides in that during different sections the riders are propelled upwards from the blast of 50 or so water jets on both sides directed upwards at an angle towards the tube. (see below).

One of the uphill sections on the Eagle Hunt water attraction [4]

These high-pressure streams are caught by pockets embedded in the sides of the tube which then, in turn, pushes the tube and riders up the incline. It’s a neat design because the water slide is not restricted to “only downhill” and other constraints from water falling due to the effects of gravity. It was thrilling to be accelerated uphill while on a water slide. I’ve never experienced that before and it was all because of the novel tube and water jets design combination.

Riders at the end of the ride with black pockets to catch water jets on the side of the tube. [4]

Interestingly, every single rider must weigh themselves before going on this ride, and must ride in a pair – no single riders allowed. Furthermore, the two riders must collectively be heavier than 150 pounds but also less than 450 pounds. Clearly, the uphill section had design constraints on both ends of that range respectively: too light and the riders might be accelerated too quickly or unpredictably; too heavy and the riders might not make it up the incline. I’m sure some people in line were a little embarrassed to have their weight publicly revealed to everyone else in the line but the great design and great experience were well worth it. (And we all felt a little motivation to lose some weight in the meantime.) - John Salmon

The Renishaw OMP60 Touch Probe System

Machining is at the center of a majority of manufacturing jobs nationwide. One of the coolest tools I have seen this summer is the Renishaw Probe that we use to locate parts in our mill. Through kinematic resistance, optical transmission, and coded signals, the OMP60 seamlessly integrates into any CNC mill. My favorite part about the design of this tool is the robust and error-resistant mechanics. People make mistakes, often, and as much as machinists believe that they are flawless at their jobs, tools break, operations fail, and parts are ruined. I have found that the Renishaw is the most resistant to operator error. It has built-in springs that prevent crashing in the z dimension. It also has electrical resistance patches that automatically turn off machine movement when something comes into contact with the probe that shouldn’t. This design principle, designing for error prevention, is an essential component of any good design. You never know what conditions people will put your products in so designing them to be as robust as possible will enable your products to have a much longer lifetime. For example, you can include more hinges on a lid/cover in case one of them fails. You could increase ribs and wall thickness on parts that need to hold a lot of weight. You can include backdoors in the code in case someone gets locked out of a program. The bottom line is that more robustness equals a longer lifetime and a cheaper overall cost for the consumer. - Andrew Cousins

The OMP60 touch-trigger probes [5]

[1] Pacific Northwest National Laboratory, “Self Healing-Cement,” https://www.pnnl.gov/available-technologies/self-healing-cement, accessed August 24, 2024

[2] Royal Institution of Chartered Surveyors, “Building a sustainable future: the incredible potential of self-healing concrete,” https://www.rics.org/news-insights/building-a-sustainable-future-the-incredible-potential-of-self-healing-concrete, accessed August 24, 2024

[3] https://arcace.ca/alternative-sustanable-construction-materials-self-healing-concrete/

[4] https://cdapress.com/news/2024/jun/09/eagle-makes-a-big-splash-at-silverwood/

[5] https://www.renishaw.com/en/standard-accuracy-machine-tool-touch-probes--32926

To cite this article:

The BYU Design Review Editorial Board. “Good Design from the Summer of 2024.” The BYU Design Review, 31 Aug. 2024, https://www.designreview.byu.edu/collections/good-design-from-the-summer-of-2024.